FCR indexable end mills from BIG KAISER with exclusive monoblock design ensure vibration-free machining - BIG DAISHOWA Präzisionswerkzeuge | BIG DAISHOWA

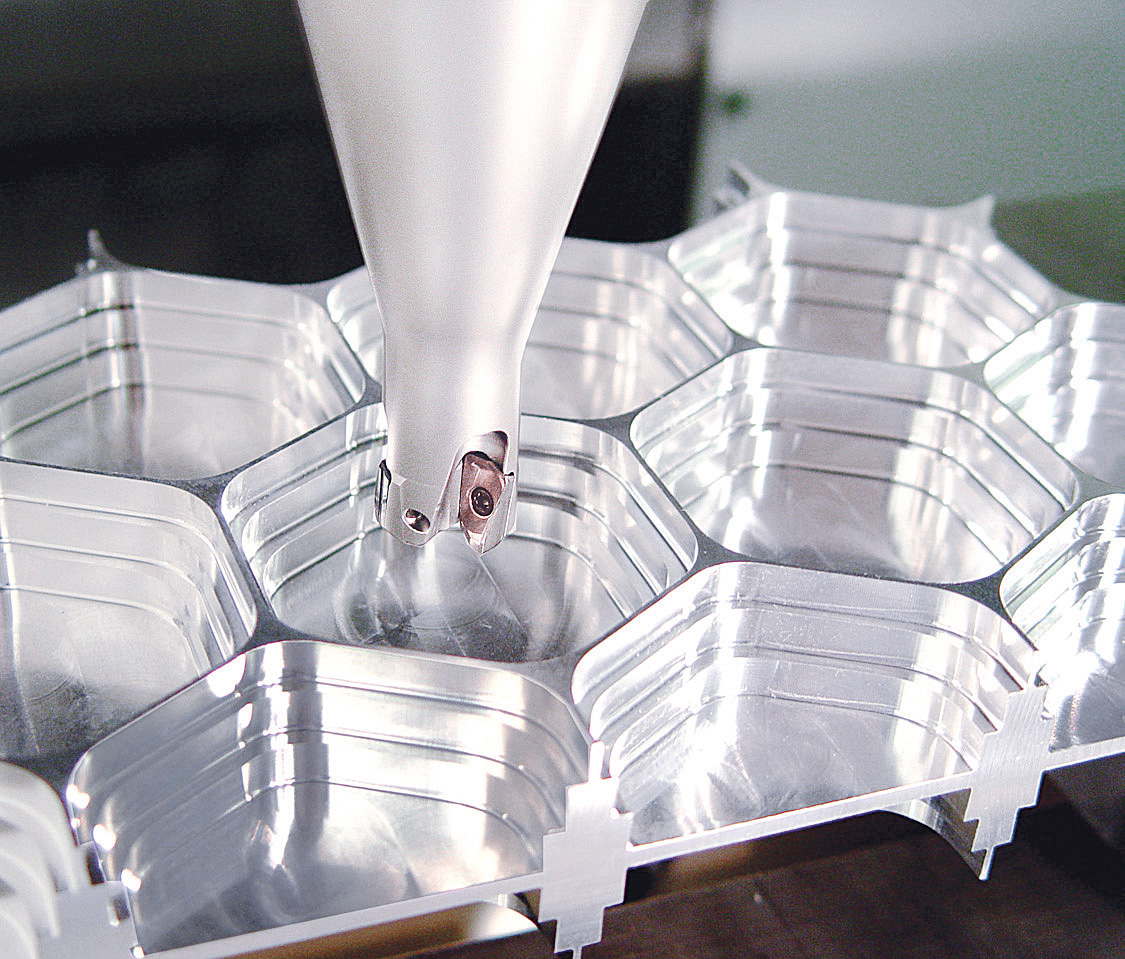

FCR indexable end mills from BIG KAISER with exclusive monoblock design ensure vibration-free machining

Ruemlang, Switzerland – November 27, 2024 – BIG KAISER, a leader in premium high-precision tooling systems and solutions for the metalworking industries and part of the BIG DAISHOWA Group, underscores the cost-saving and efficiency-enhancing benefits of its CK modular tooling system for machine shops worldwide.

As demand for cutting tools grows across industries such as automotive, construction, aerospace, and defense, the global market is projected to reach over $120 billion by 2030, expanding at a CAGR of 6.2% (Virtue Market Research). Amid rising costs for energy, labor, and materials, manufacturers face increasing pressure to balance quality with financial sustainability.

Introduced in 1971 by Heinz Kaiser, the CK modular tooling system transformed precision machining by integrating advanced turning tools with basic holders. This patented innovation allows manufacturers to continuously adopt state-of-the-art tools without compromising quality or increasing costs. The CK system excels in precision milling, as well as rough and fine boring, while offering unparalleled adaptability and cost efficiency.

“For over 50 years, the CK system has delivered a reliable, functional, and economical solution for machine shops,” says Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER. “Its backward compatibility ensures tools remain usable for decades, enabling shops to seamlessly update their tooling while leveraging existing investments.”

The CK system reduces tooling costs by eliminating the need for dedicated monoblock tools for each task. Instead, users can combine modular components to achieve precise results. Its micrometer-level repeatability optimizes cutting conditions, prolongs tool life, and lowers overall expenses. The system supports a broad range of applications, from rough and fine boring to anti-vibration and digital tool solutions, and integrates with all major machine tool interfaces, including BIG-PLUS spindles.

Designed for versatility, the CK system enables shops to tailor tool assemblies for specific needs, such as machining deep cavities. Continuous innovations, including lightweight aluminum components and balance compensation, enhance performance and address evolving customer demands. All CK components are readily available, ensuring efficiency and minimal downtime.

BIG KAISER remains committed to advancing precision machining through innovative tooling solutions, setting new standards for quality and reliability.