BIG DAISHOWA introduces new center-through-coolant angle heads with up to 70 bar internal pressure - BIG DAISHOWA Präzisionswerkzeuge | BIG DAISHOWA

BIG DAISHOWA introduces new center-through-coolant angle heads with up to 70 bar internal pressure

Ruemlang, Switzerland – December 16, 2025 – BIG DAISHOWA, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announces a major expansion of its fixed 90-degree angle head lineup with the new TAG90 center-through-coolant angle head and AG35 high-pressure coolant adapters.

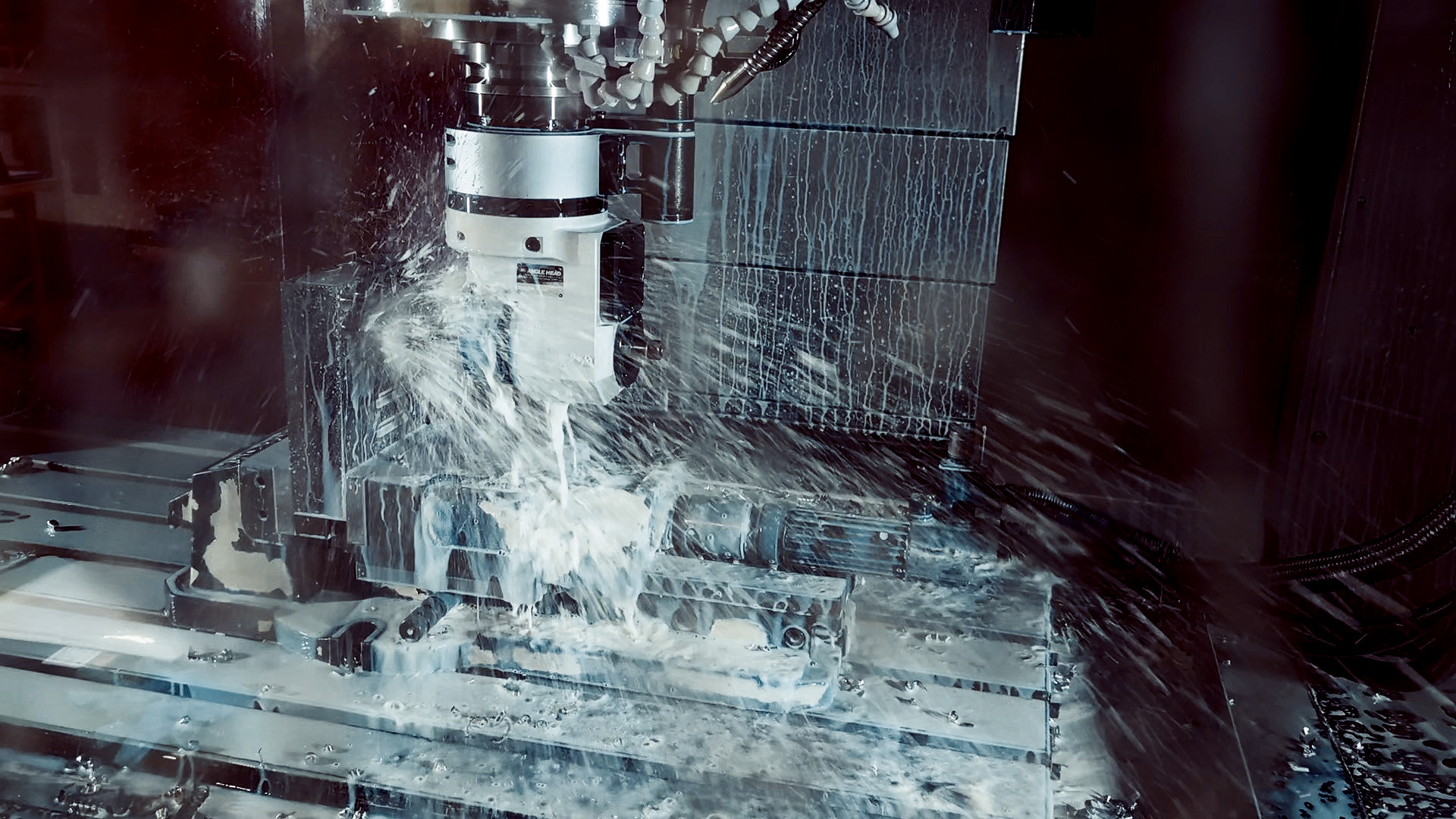

These innovative angle heads deliver coolant directly from the machine spindle to the cutting edge, without passing through the stop block, significantly improving cooling efficiency, chip evacuation and tool life, especially in hard-to-machine materials used in aerospace and energy industries.

With coolant pressures up to 70 bar and coolant flow rate up to 30 l/min, the new system allows precise coolant delivery straight to the cutting edge. This ensures stable machining of exotic alloys such as titanium, Inconel, and cobalt-chrome, while reducing heat generation and extending tool life.

Customers can select from two configurations:

· Build-up type angle heads, featuring interchangeable AG35 high-pressure coolant adapters, including New Baby Chuck and Side Lock types for flexible applications.

· HMC type angle heads, offering a high-rigidity milling chuck design for maximum accuracy and stability.

The modular concept allows users to adapt quickly between operations, while the new coolant adapter technology provides robust sealing and extended lifetime, resistance to mechanical wear and unaffected by the internal fraction heating that typically shortens gasket life in other systems.

BIG DAISHOWA’s angle head lineup enables operators to perform vertical and horizontal machining in a single setup, improving efficiency and accuracy while reducing cycle times in operations like drilling and milling. The addition of center-through coolant now enhances these advantages even further, making it ideal for complex components in energy turbines, aircraft structures and other high-performance applications.

“After years of customer demand, we are proud to finally introduce an internal-coolant angle head that meets the real-world challenges of aerospace and energy machining,” says Giampaolo Roccatello, Chief Sales & Marketing Officer Europe at BIG DAISHOWA Europe. “With pressures up to 70 bar and direct coolant delivery to the cutting edge, these angle heads bring a step change in productivity, tool life and reliability, especially for exotic materials.”

By integrating high-pressure coolant delivery directly into the angle head, BIG DAISHOWA now offers manufacturers an all-in-one solution for difficult materials and complex geometries. The system eliminates the need for external coolant lines via the stop block, simplifying installation and reducing maintenance requirements.

With this innovation, BIG DAISHOWA continues to push the boundaries of precision tooling, helping manufacturers achieve higher process reliability, improved chip evacuation, and superior surface quality in demanding machining environments.

# # #

About BIG DAISHOWA Europe

BIG DAISHOWA Europe is part of the BIG DAISHOWA Group. Headquartered in Osaka, Japan, with a robust global presence supported by facilities in Europe, North America and Asia, BIG DAISHOWA operates with a team of 900 skilled professionals dedicated to the advancement of the metalworking industry. BIG DAISHOWA continues to set new standards in the global boring tool industry by designing and manufacturing state-of-the-art electrical and electronic auxiliary equipment, including wireless control and monitoring systems. The comprehensive product range includes over 20,000 precision tools such as collet chucks, hydraulic chucks, boring heads, indexable inserts and measuring tools, all manufactured to the highest standards of quality and precision. www.bigdaishowa.eu