BIG DAISHOWA launches MEGA Micro Nuts for high-performance coolant supply in micromachining - BIG DAISHOWA Präzisionswerkzeuge | BIG DAISHOWA

BIG DAISHOWA launches MEGA Micro Nuts for high-performance coolant supply in micromachining

Ruemlang, Switzerland – May 15, 2025 – BIG DAISHOWA, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announces the launch of the MEGA Micro Nuts - an innovative trio of coolant control accessories for the MEGA Micro Chuck. Specifically developed for micromachining, these products enhance cutting performance and tool life in demanding applications, particularly within the medical sector.

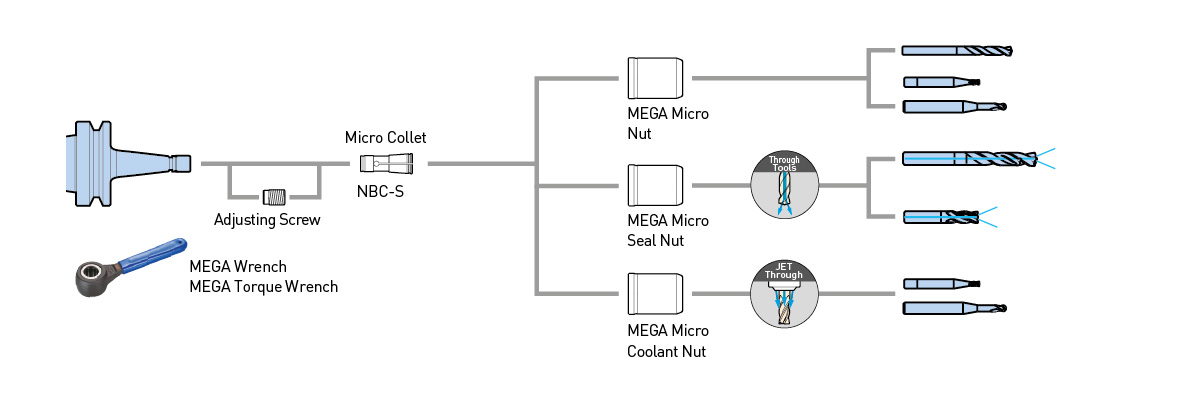

The MEGA Micro Nut series includes three specialised nuts: the MEGA Nut, MEGA Micro Seal Nut, and MEGA Micro Coolant Nut. Each delivers a unique coolant delivery method and gripping performance, giving users the flexibility to optimise their setup based on material, tooling and machining strategy. Together, they form a comprehensive solution for precision cutting of challenging materials such as titanium and cobalt chrome, which are commonly used in medical implants and instruments.

"Micromachining requires not just accuracy but intelligent coolant control, especially in the medical sector where we work with materials that are difficult to cut and highly heat-sensitive," says Giampaolo Roccatello, Chief Sales and Marketing Officer Europe at BIG DAISHOWA Europe. "The MEGA Micro Nut series enables our customers to achieve better surface quality, reduced cycle times and improved chip evacuation in even the most difficult conditions – so machining is possible with small tools, at high speeds and with materials that were impossible before, without excessive cost."

Each nut in the series is compatible exclusively with the MEGA Micro Chuck collet chucks, which are ultra slim chucks designed for micromachining. With three nuts in the series, customers have the flexibility to choose the best solution for their application:

· MEGA Nut: Standard clamping nut offering high gripping torque, excellent balance, and small outer contour - ideal for general finishing with external lubrication.

· MEGA Micro Seal Nut: Enables internal coolant delivery through the cutting tool, suitable for deep drilling and fine machining when using internally cooled tools.

· MEGA Micro Coolant Nut: Provides external peripheral coolant directed at the cutting edge for optimal chip evacuation - especially when internal coolant channels are not available. This patented design significantly enhances tool life and surface finish.

With 32 versions across three models and four sizes, the MEGA Micro Nuts offer exceptional versatility for applications in medical, dental, watchmaking and electronics manufacturing.

The launch reflects BIG DAISHOWA's continuous commitment to innovation through Swiss-based R&D and customer-driven design. As micromachining demands grow in complexity, the MEGA Micro Chuck and MEGA Micro Nuts series position BIG DAISHOWA at the forefront of precision tooling for tomorrow's high-performance industries.

# # #

About BIG DAISHOWA Europe

BIG DAISHOWA Europe is part of the BIG DAISHOWA Group. Headquartered in Osaka, Japan, with a robust global presence supported by facilities in Europe, North America and Asia, BIG DAISHOWA operates with a team of 900 skilled professionals dedicated to the advancement of the metalworking industry. BIG DAISHOWA continues to set new standards in the global boring tool industry by designing and manufacturing state-of-the-art electrical and electronic auxiliary equipment, including wireless control and monitoring systems. The comprehensive product range includes over 20,000 precision tools such as collet chucks, hydraulic chucks, boring heads, indexable inserts and measuring tools, all manufactured to the highest standards of quality and precision. www.bigdaishowa.eu